The importance of manufacturer markings and stamps on fire safety glass

Despite marking or product identification stamps being a requirement on all safety glass products, there is still room for misunderstanding and confusion within the industry about what they are for and what they actually tell us.

Here, Andy Lake, Pyroguard’s Sales Director UK & IRE explains the markings on fire safety glass and how to read them.

According to Section 7 of BS 6262-4:2005, all safety glass must be “clearly and indelibly marked” with information relating to its manufacture and classification. This mark must be in such a position and remain clearly visible on the pane after installation, aiding building inspectors and other construction professionals with easy identification and verification of the product performance.

Making your mark

While there is no standard layout for the mark, meaning that each glass manufacturer and processor will often have its own design and style, there are three pieces of information that the mark must include:

- The name or trademark of the manufacturer, merchant or installer

- Identifier of the product standard that the safety glass conforms to (such as EN12150 or EN14449)

- The impact safety classification according to EN12600

Interestingly, there is no direct regulation or standard specifically relating to the marking of fire glass but it is good practice to include one. This mark can be applied, for example, by acid etching or sandblasting at the final stages of manufacture or secondary processing.

So, why do we need to stamp?

Markings on fire safety glass makes important information about the product readily available, helping the right product or classification to be easily identified and provides assurance that it complies with all the required safety regulations.

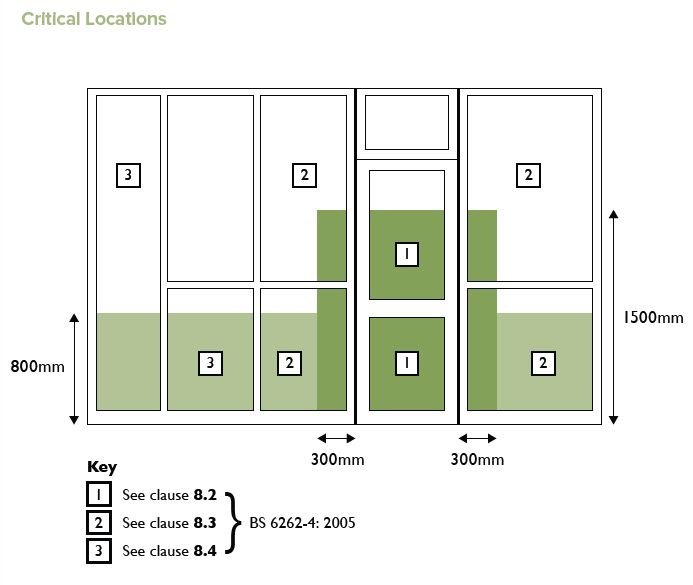

The requirement of safety glass and impact resistance is primarily dictated by critical locations, such as the area around a door or low-level areas with the danger of impact.

Additionally, areas that require a line load or protection from a risk of falling will generally have a requirement for safety glass and so require product marking. Here, stamps or marks make it easier for building inspectors to identify safety glass installations and to confirm their correct installation.

What does it say?

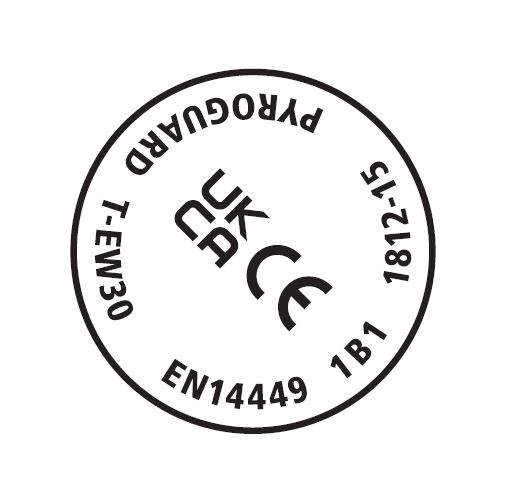

As a safety glass product, the stamp or mark must include the product standard and impact classification as a minimum. At Pyroguard, we take this one step further and also include the product type and fire classification, on all our glass products, further aiding the inspection and identification process.

Example:

- Pyroguard T = Product name and manufacturer

- EW30 = EW30 fire classification, providing Integrity & Radiation performance for 30 minutes

- EN14449 – manufactured to product standard for laminated safety glass

- 1812-15 = CE / UKCA marking registration reference

Meanwhile, our cuttable stock products can appear slightly different, featuring 1B1 = impact classification, according to EN 12600 both the Pyroguard name (as the product title) and also the supplier or processor’s details.

Double- and triple-glazed units can naturally become more complicated, with the potential for two or more different marks to be included on the glazing system – one for the safety glass itself and then individual marks for the additional counterpanes, as they may also be a form of safety glass in their own right.

Another purpose of the markings on fire safety glass can be to demonstrate that the product complies with CE or UKCA marking. The new UKCA Mark falls under GB legislation and, similarly to CE marking, is a guarantee to customers and consumers that a product can be used safely and has met all applicable and designated standards, relevant environment legislation and health and safety regulations.

Identifying fire safety glass

Generally speaking, marking on fire safety glass is all about identification and traceability – two key topics of conversation when it comes to fire safety and, more generally, building safety. The mark enables you to look at a piece of glass and instantly identify who manufactured it and what standard the glass conforms to. It can also be used to help verify that it has been installed in the correct location, as well as differentiating safety glass from standard glass.

Traceability is particularly important within both the fire safety industry and wider construction industry, a topic that featured heavily in Dame Judith Hackitt’s ‘Building a Safer Future’ review and report. Indeed, having an understanding of where a building material has come from, who is responsible for it and what its performance characteristics are, are all vital, ensuring a flow of information through the supply chain and offering trust and peace of mind. Effective traceability also means that any queries or problems can be easily rectified, with asset owners and facility managers able to promptly identify both the product and the manufacturer or supplier responsible.

Marks on safety glass can initially appear confusing. However, they do serve an important purpose, providing a wealth of information on a product’s production, makeup and performance classification. While all manufacturer marks may be different in appearance, having an understanding of the common data and information contained within the stamp can help in deciphering the text.

For more information, please contact us.

Numbers explained:

Toughened glass – EN 12150

Laminated glass – EN14449

DGU – EN1279