Global expertise in fire safety glass

The world’s leading independent provider of fire safety glass for timber, steel and aluminium applications.

Find out moreOur fire safety glass products

We provide the widest range of tested and certified fire safety glass solutions on the market enabling architects, specifiers and installers to achieve their vision of safe and beautiful living and working spaces.

Pyroguard Advance

Product type: Cuttable

A range of stockable and cuttable fire safety glass which provides the full range of protection from 30 minutes integrity and radiant heat reduction to 60 minutes heat insulation.

Pyroguard Advance offers cuttable EI products at market leading thicknesses with exceptional fire protection at larger sizes. This unique ‘next generation’ product offers superior levels of UV stability, excellent light transmission and is easy to process and install.

View allPyroguard Rapide Plus

Product type: Cuttable

A range of cuttable fire safety glass which provides integrity and heat insulation for 30 and 60 minutes (EI Classification). This stockable product provides application flexibility into timber, steel and aluminium framing systems and 1B1 impact performance at short lead times.

View allPyroguard Rapide

Product type: Cuttable

A range of cuttable fire safety glass which provides integrity and radiant heat reduction for 30 and 60 minutes (EW Classification). A market leader for ease of processing and installation, much of the range can be cut by hand with no additional preparation. A trusted solution in the market for over 20 years, this range offers short lead times and exceptional visual quality.

View allPyrostem

Product type: Cuttable

Entry-level cuttable, wired fire safety glass which provides integrity only protection against the passage of flames, smoke and toxic gases for 30 and 60 minutes (E Classification). Used in like-for-like refurbishment projects demanding an economical glass with the appearance and performance of Georgian polished wired.

View allPyroguard Protect

Product type: Toughened

A range of toughened fire safety glass which provides integrity and heat insulation for 30 to 180 minutes (EI Classfication). The solutions provide 1B1 impact classification offering high performing acoustic properties and UV stability.

View allPyroguard Firesafe

Product type: Toughened

A range of modified toughened fire safety glass which provides integrity only protection against the passage of flames, smoke and toxic gases for 30 minutes (E Classification) and in the case of the coated range, also radiation protection (EW Classification for up to 60 mins). This lightweight monolithic solution provides exceptional impact resistance combined with high visual quality, is UV stable and available on short lead times.

View allPyroguard Infinity

Product type: Toughened

A range of fire safety glass certified for butt joint applications, providing integrity and heat insulation for 30 and 60 minutes (EI Classification). No vertical frame profiles required, providing visually appealing seamless partitions between rooms and corridors.

View allPyroguard Marine

Product type: Toughened

A range of toughened and gel-filled fire safety glass providing integrity only and integrity and insulation protection against the passage of flames, smoke and toxic gases from 30 to 60 minutes. The solutions provide 1B1 or 1C1 impact classification, high-performance acoustic properties and UV stability.

View all

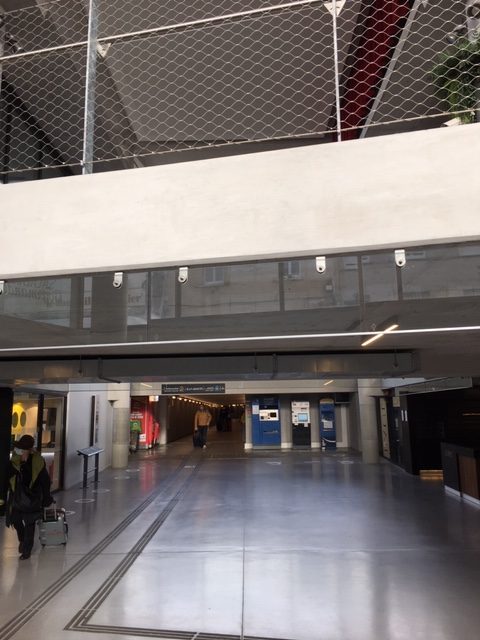

Our case studies

About us

Pyroguard, part of the Technical Fire Safety Group, is the leading independent manufacturer and supplier of high performance fire safety glass solutions.

With the broadest range of both cuttable and toughened products on the market, we can help you select the correct product for your chosen application. All our products are supplied with the required certification giving you the ultimate peace of mind.

Read more

What our customers say

Working with Pyroguard on the Deanston Wharf project was a great success, especially with regards to the technical support they offered. Given the stringent fire safety regulations and the emphasis on traceability, we had to supply our client with comprehensive datasheets, test evidence and certifications. Thanks to the support from Pyroguard and Q-Railing, we were able to deliver all of this to the client, smoothly and efficiently.

Noel Gilmartin, Operations Manager , Elite Architectural Systems

Find out morePyroguard Protect’s high visual appearance helped to maintain the light and open interior that the architect desired, while its multi-functionality proved key in delivering improved acoustic control and impact resistance – something which was a clear priority when designing the new academy.

Ruud van Dal, Sales and Operations Manager, JM Van Delft & zn

Find out moreWorking with both Jansen and Pyroguard, these glazing systems and screens were designed not only for their minimalistic aesthetic and ability to allow maximum light into the interior space, but more importantly to comply with the fire strategy of the building. Pyroguard Protect fire safety glass enabled the creation of fire safe compartments on each floor and lobby, ensuring the protection of future building occupants.

David Skelly, KCC Group

Find out moreIn the newsroom

View all